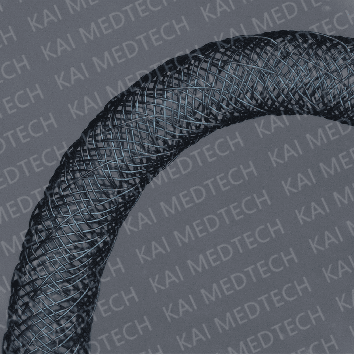

Nitinol Braiding

Nitinol Braiding

KAI MedTech provides repeatable structures with high precision

KAI MedTech provides repeatable structures with high precision

KAI's braiding technology offers carrier ends ranging from 12 to 96, each with an independent control system to ensure that the production requirements of these braiding structures are met and heated to form the preferred size. We are able to carry out further processing, such as coatings, to meet more specific needs.

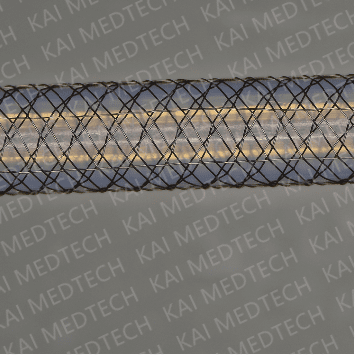

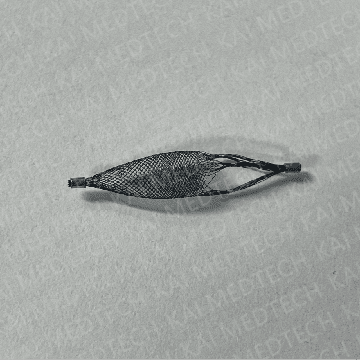

Multi-Pitch Braiding

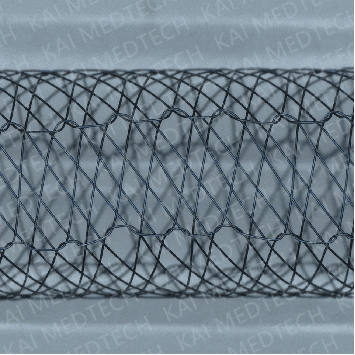

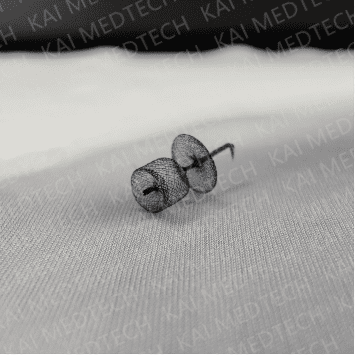

Z-axis Braiding

Z-axis Braiding

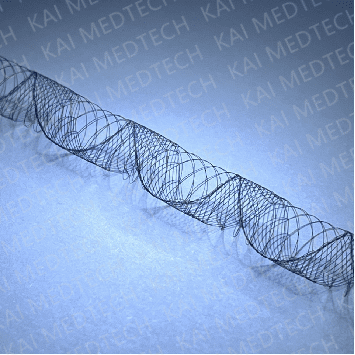

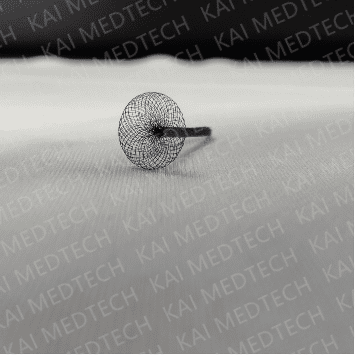

Spiral Braiding

Spiral Braiding

Hook Braiding

Hook Braiding

Post-Processing for Implantable Braids

Post-Processing for Implantable Braids

For braidings of various shapes, KAI MEDTECH can also perform post-processing to obtain more specific products, such as Surface treatment, Wire connections and Secondary shape settings.

Surface treatment: We can electropolish the surface of the braided products to obtain smooth surface, low roughness and excellent corrosion resistance.

Wire connections: We can process the loose ends of the braided products by welding, bonding, etc., to realize the parallel wire connection of the wire material, or the fusion connection at the wire head, improve the structural stability, while avoiding the damage of blood vessels.

Secondary Shape Settings:

KAI MedTech offers a wide range of secondary shape settings

The Braided Medical Devices list of KAI MedTech:

The Braided Medical Devices list of KAI MedTech:

·Braided Stents-Neuro & Heart Implants

·Blocking Devices

·Retrieval Devices

·Embolic Protection Devices

·Middle Layer of Catheters

THE MATERIALS FOR BRAIDING

THE MATERIALS FOR BRAIDING

The materials used in the braiding device will affect the performance of the braiding machinery. KAI MedTech uses different wires in its medical braiding applications, such as:

·Nitinol Wire ·MP35N Wire ·DFT Wire